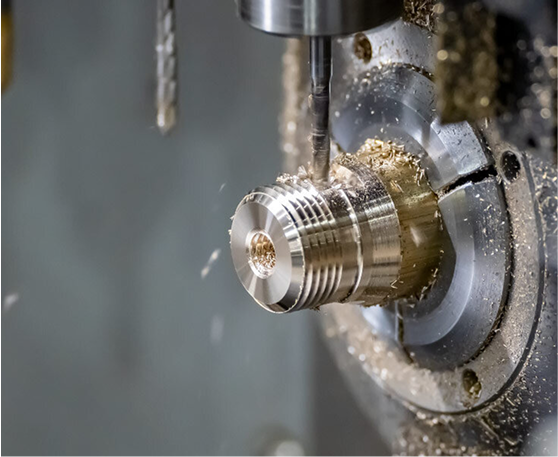

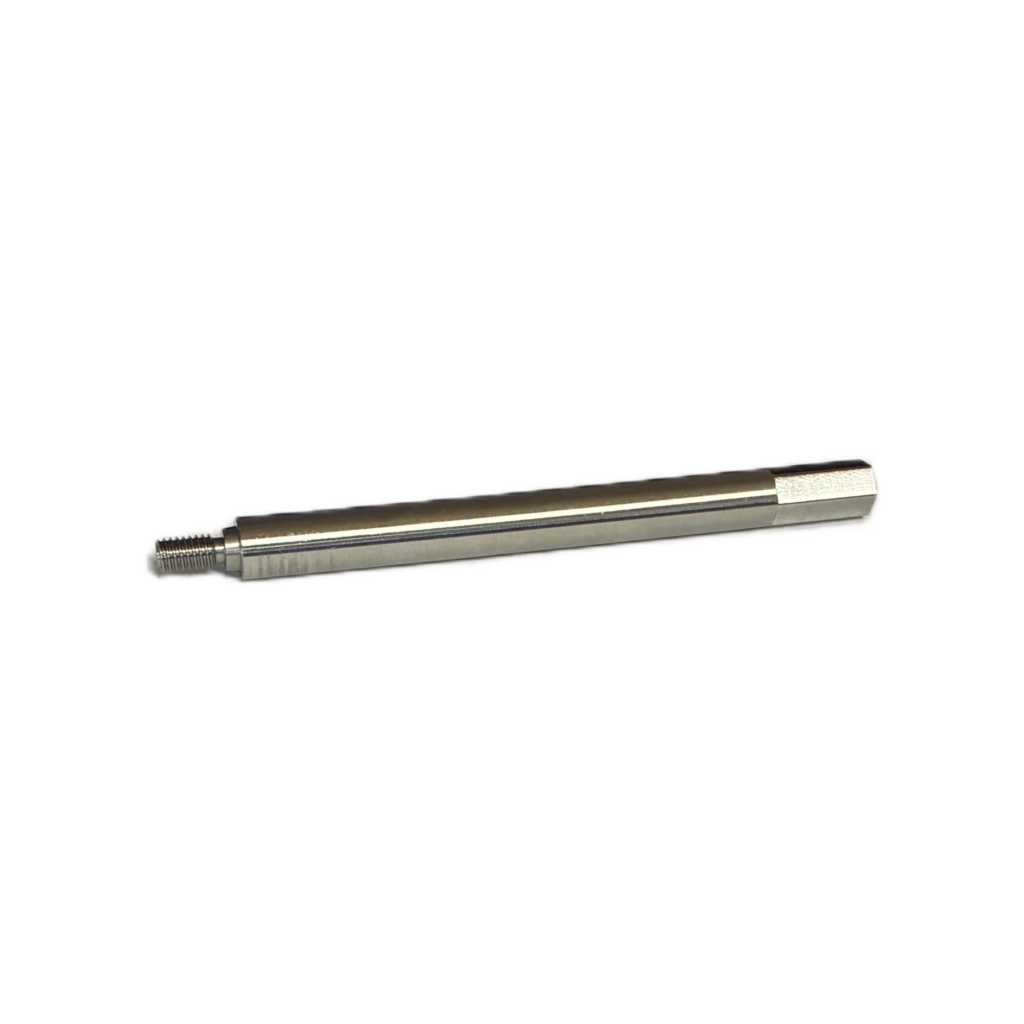

CNC Swiss machining is a highly specialized manufacturing process designed to produce complex, ultra‑precise components with exceptional consistency. Unlike conventional machining, Swiss machines utilize a sliding headstock that supports the workpiece close to the cutting tool. This unique design minimizes deflection to machine parts with s high length to diameter ratio. Swiss machines produce parts with tight tolerances, superior surface finishes, and intricate geometries.

Originating in Switzerland more than a century ago to meet the demands of the watchmaking industry, Swiss machining quickly became synonymous with precision craftsmanship. Today, this technology has evolved into a cornerstone of modern manufacturing, delivering unmatched accuracy across industries where reliability and performance are critical.

Our CNC Swiss machines are trusted to manufacture mission‑critical components for:

Our team combines decades of machining expertise with state‑of‑the‑art CNC Swiss technology to deliver parts that meet the most demanding specifications. Whether you need prototype development or full‑scale production, we provide solutions that emphasize:

Contact Us to Learn How Caldwell Manufacturing Can Meet Your Precision Metal Product Manufacturing Requirements