Caldwell Manufacturing is a premier producer of high-quality precision machined components since 1987. We exceed our customers’ high expectations by using technically advanced equipment, strict quality control, responsive customer service and competitive pricing. Caldwell Manufacturing is an excellent choice and a valuable partner for your outsourcing demands

We manufacture your parts to print and deliver on time, so you never have to worry about production lines going down again.

We are passionate about helping companies

confidently build their products with our

precision machined parts.

CNC Swiss machining is a precision manufacturing technique that utilizes computer numerical control to produce highly accurate, complex parts. This method excels in creating small, intricate components with tight tolerances, leveraging a sliding headstock to improve accuracy and surface finish. It started in Switzerland over a century ago to support their growing watchmaking industry. It has evolved over time and is now widely used in industries such as aerospace, medical devices, and electronics.

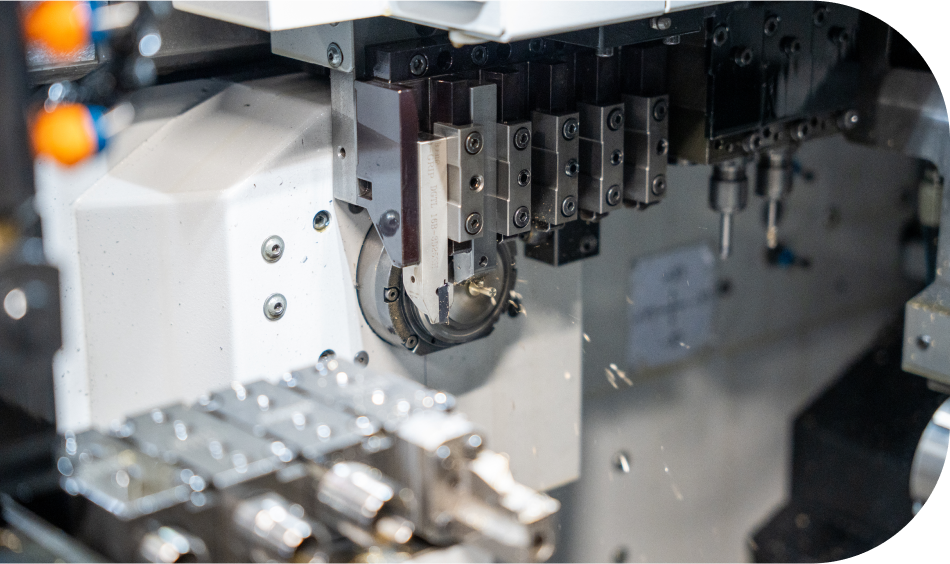

Our CNC multi-axis live tool lathes combine precision turning with advanced milling capabilities, allowing us to create complex parts in a single setup. Combining both milling and turning on the same machine ensures faster production, repeatable results and no WIP reduce your cost. It’s perfect for industries like valves and pumps, gun manufacturing, and custom hardware. Our multi-axis lathes provide unmatched flexibility and efficiency for your precision machining needs.

Precision 4-axis CNC milling utilizes advanced CNC technology to achieve high accuracy and repeatability in machining complex geometries. With an additional rotational axis, it efficiently creates intricate shapes in various materials while maintaining tight tolerances. Integrated CAD/CAM software streamlines design and programming, consistent production across industries such as Oil and Gas, and Machinery and Industrial Equipment

We offer CNC turning services for mid-range volume parts. CNC machining allows for shorter setup times and faster turnaround on complex part designs. Our commitment to automation and utilization of the fastest CNC Machining Centers guarantees shorter cycle times and consistent quality

Centerless grinding is a precision material removal process we use as a secondary operation for our machined parts. This technique allows for high accuracy and consistency, producing components with tight tolerances and excellent surface finishes. Commonly used for stems, centerless grinding facilitates rapid production and effective material removal, making it ideal for high-volume applications.

Saw cutting is a precision technique used to efficiently cut hard metal bars into specific lengths and shapes. This method ensures clean edges and minimal material waste, making it ideal for manufacturing applications. It allows for accurate sizing and preparation of material for our lathes and mills

Laser engraving is a precision technique that utilizes a focused laser beam to etch or mark parts with high accuracy and detail. This method efficiently creates intricate designs, identifiers, and patterns while ensuring clean edges and fine resolution. It is widely used in manufacturing for permanently identifying your part with information such as part number, logo or orientation allowing for rapid production and customization to meet specific industry standards.

We offer cleaning and passivation services to meet ASTM A 967, ensuring the removal of contaminants and enhancing corrosion resistance. Our process improves the durability and performance of metal parts, making them ideal for industries like aerospace, medical, and electrical connectors. We deliver clean components that meet the highest industry standards.

Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for industries where weight and performance matter. We produce aluminum parts for aerospace, automotive, medical devices, and industrial machinery. Its excellent machinability and versatility allow for the production of components such as engine parts, housings, frames, and heat exchangers.

Titanium is a strong, lightweight, and corrosion-resistant metal with a silvery-gray appearance. It's known for its high strength-to-weight ratio and is used in aerospace, medical implants, and engineering. Titanium is resistant to oxidation and most acids, non-toxic, and biocompatible, making it ideal for medical devices.

Inconel is a high-performance superalloy used in extreme environments, such as those found in gas turbines, aerospace, and chemical processing. It excels in high-temperature, high-pressure applications. We produce Inconel components like turbine blades, exhaust systems, heat exchangers, and pressure vessels, ensuring maximum durability and performance even in the harshest conditions.

Vespel is a high-performance plastic known for its ability to withstand high temperatures and harsh chemicals. This material is ideal for applications in the aerospace, automotive, and semiconductor industries. Caldwell Manufacturing produces Vespel components such as seals, bearings, bushings, and gaskets, which offer high wear resistance, reduced friction, and exceptional dimensional stability.

Plastics are versatile, cost-effective materials used in a wide variety of industries. Caldwell Manufacturing machines various types of plastics, such as PTFE, PEEK, and UHMW, for applications in medical devices, electronics, automotive, and consumer goods. Common plastic components include housings, insulation, seals, and custom fittings, designed to meet specific performance needs.

Monel is a corrosion-resistant alloy primarily used in marine, chemical, and petrochemical applications. Its resistance to seawater, acids, and alkalis makes it perfect for components exposed to harsh environments. We manufacture Monel parts such as marine hardware, valves, pump shafts, and chemical processing equipment, ensuring durability and longevity in aggressive conditions.

Stainless steel is one of the most widely used materials due to its strength, corrosion resistance, and aesthetic appeal. Caldwell Manufacturing produces stainless steel components for industries like food processing, medical devices, automotive, and construction. We machine parts like surgical instruments, machinery components, structural frames, and fasteners, ensuring they meet high standards of durability and precision.

Nitronic 50 is a high-performance stainless steel alloy that offers superior corrosion resistance and excellent strength at high temperatures. It's commonly used in industries such as aerospace, marine, and chemical processing. At Caldwell Manufacturing, we produce Nitronic 50 components like heat exchangers, pump shafts, and marine hardware, offering outstanding performance in harsh environments.

At Caldwell Manufacturing, our success is built on a foundation of strong leadership, dedicated to driving excellence in everything we do. Our leadership team brings a wealth of experience, expertise, and a shared commitment to quality and innovation. Each member of our team plays a crucial role in ensuring that we deliver the highest standard of precision CNC machining to our clients across a wide range of industries. Read more

© 2025 Caldwell Manufacturing. All Rights Reserved

Design and Developed By Techole.com